Shot my last match of the year in Sunday in the 11th hour of the 11th day of the 11th month. Not planned but it seemed a fitting way to end the season.

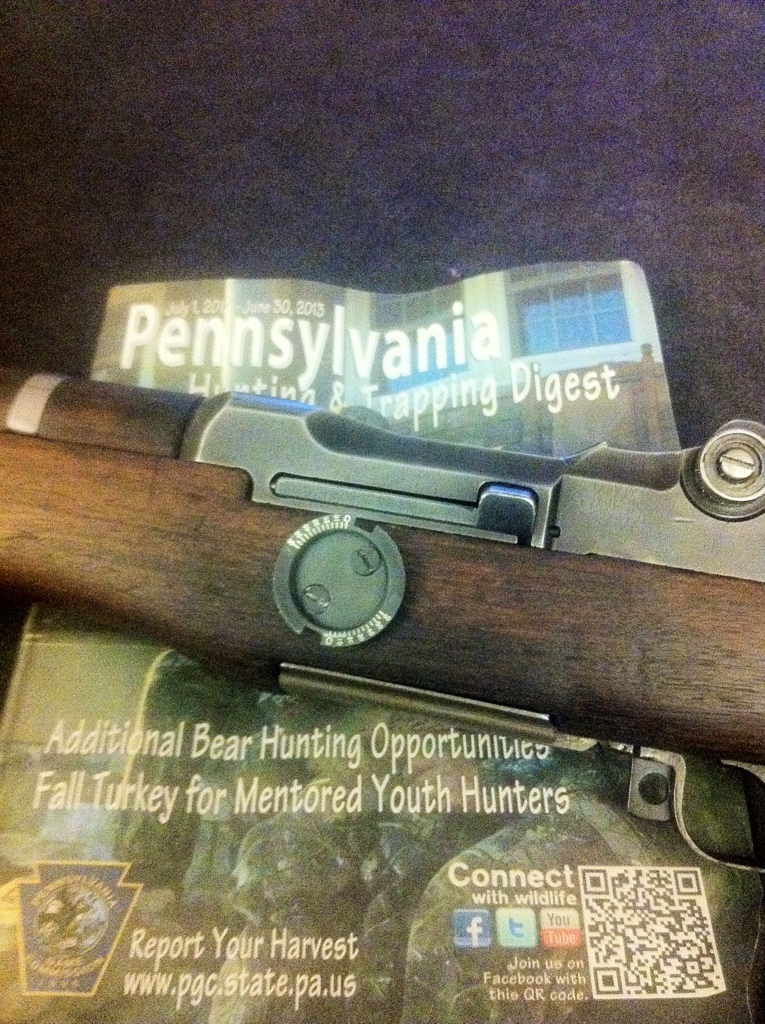

I intended to take the 1917 for Armistice Day however with hurricane sandy and getting ready for deer season I didn’t have as much time as I wanted to practice and I didn’t want to end the season with 87 point. I shot pretty well the dry fire practice and changes I made to my sling really helped.

Now I just need to find some time to give my Garand a good detail strip and clean and start practicing for next season. I already have my hotel booked for Perry in the summer!

Dry fire practice